Liquid Waste Disposal Perth is vital to maintaining environmental sustainability and public health. It involves the collection, treatment, and disposal of various liquid wastes from industrial, commercial, or domestic activities.

Some liquid wastes require extensive treatment before they can be disposed of safely. Such treatments include: screening, sedimentation and aerobic processes.

Methods of disposal

Liquid waste disposal involves the treatment and dumping of liquid waste materials that can pose a threat to the environment and human health. Such wastes may be generated in factories, households, and agricultural sites. They include sewage effluent, waste water, industrial chemicals, oil-based paints, edible and motor oils, and other liquid byproducts.

The most common way to dispose of liquid waste is through landfills. However, this type of disposal is prone to a number of problems, including the risk of toxic substances leaching into groundwater and the possible explosion of dangerous gases in landfills.

This is why it is important to consider alternative methods of disposal, such as incineration and waste-to-energy processes. These alternatives not only ensure that liquid waste is disposed of in a safe and environmentally friendly manner, but also helps to reduce the amount of waste that goes into landfills.

Many liquid waste disposal techniques involve screening and separation. This is done to remove large particles and non-organic contaminants. The resulting material is then separated into different categories, depending on its chemical composition. The most contaminated wastes are then sent for more intensive treatments.

Some of these treatments are more effective than others. For example, the use of disinfectants is crucial for removing harmful pathogens and preventing diseases in the environment. Common disinfection methods include chlorination and UV disinfection.

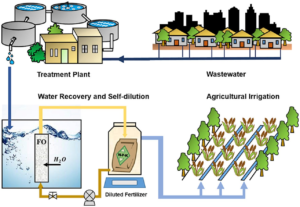

Other methods of liquid waste disposal include land application and deep-well injection. Land application entails spreading the liquid waste across land, which can be used as a fertiliser or for crop irrigation. Another option is to inject the liquid waste into deep wells, which can be used for groundwater remediation.

This method is especially useful for hazardous liquid wastes, such as those containing chemicals and acids. In the case of acidic waste, incineration is particularly effective, as it can be converted into ash and gases through high-temperature combustion. The ashes can be used as an alternative fuel, and the gases can be utilized for energy production.

Another method of disposal is called solidification, which is used for non-hazardous liquid waste. In this process, binding agents are added to the waste until it forms a compact and rigid solid. This is then shipped to approved landfills or waste-to-energy facilities for incineration and energy generation.

Despite these methods, it is important to remember that the most suitable disposal method depends on the specific substance and its properties. For example, the use of incineration for sewage and other domestic waste is not recommended, as it could pollute groundwater.

In addition, it is important to find a disposal method that complies with local and federal regulations. The best way to do this is to work with a liquid waste disposal company that has a facility equipped for the proper treatment of all types of waste. This can help to avoid fines and other penalties that may be imposed on businesses that are not following the appropriate guidelines. Also, working with a company that recycles and reuses its own waste can save money and resources in the long run.

Hazardous waste disposal

The way in which liquid waste is disposed of can have a significant impact on the environment. This is why it is important to follow proper disposal practices and dispose of the waste correctly. There are several ways to dispose of liquid waste, including incineration and landfills. Alternatively, you can use biological treatment methods to convert the waste into organic fertilizer. However, it is important to determine whether the waste is hazardous or non-hazardous before proceeding with any disposal method. Hazardous wastes contain substances that can harm the environment and people if they are released into the water. They also have to be handled and disposed of according to strict guidelines set by law. This is because they can pose a danger to human health and can cause diseases and toxic exposure if inhaled or ingested. There are many different types of liquid waste that can be considered to be hazardous, from oil and grease to raw chemicals and controlled substances. Some of these are easily identifiable by the symbols found on the label, such as flammable, poisonous or gas under pressure. Other examples include detergents, paint thinners and wood preservatives.

Some types of liquid waste can be treated and recycled, such as flammable liquid waste, which can be converted into industrial fuel. This method of disposal has the advantage of reducing the risk of environmental contamination. In addition, it can reduce the amount of hazardous waste that ends up in landfills. The only drawback is that it can take a long time for the process to complete.

Another type of liquid waste can be treated with chemical disinfection to prevent the spread of disease. This method involves mixing the waste with strong chemical disinfectants and rinsing it to remove the chemical residue. This method is effective for waste that can be shredded to ensure good contact with the disinfectants. Other ways to treat hazardous waste include land application and biological treatment. The former involves spreading the waste on a tract of land and adding microbes that can metabolize it. The site is then covered with a layer of soil and the process is monitored to ensure that the waste is not leaching into groundwater.

Biological treatment of liquid waste includes the use of microbes to break down the chemicals and nutrients. This method is a cost-effective and environmentally friendly option for disposing of organic liquid wastes. It is also an efficient option for converting sewage into fertilizer. It can also be used to break down contaminated soils. The only drawback is that the process can take a long time to complete and is not suitable for large volumes of liquid waste.

Another option for discarded liquids is to store them safely in sealed containers until they can be disposed of properly. This can be done by using collection days for household hazardous waste (HHW) or buying and storing less toxic alternatives. You can also try reusing empty containers and taking your old paint cans to the recycling center.

In this study, backwash flows of intensive recirculating aquaculture systems were captured and dewatered in simple geotextile bag filters. The biosolids were amended with polymer plus alum, ferric chloride, or hydrated lime to evaluate how coagulant choice impacts nutrient and carbonaceous biochemical oxygen demand (cBOD5) leaching from the filtered effluent and the final composition of bag-captured biosolids.

Alum-treated biosolids showed the highest removal of total suspended solids (TSS), followed by lime and ferric chloride. In contrast, adsorption of organic acids and cBOD5 were significantly higher in the hydrated lime and ferric chloride treatments. This indicates that adsorption of organic acids is critical for effective treatment and degradation of dissolved nutrients in geotextile bag filters.

As a result, a simple and economical geotextile bag filter may be able to effectively bind dissolved phosphorus in aquaculture sludge for disposal by land application or composting. However, the alum and hydration treatments did not prevent the mineralization of DRP within the bag filter. As a result, a significant amount of phosphorus was released into the filter filtrate.

A newer and more advanced technology is the use of a dewatering tower, which allows the bag to be lifted and pushed by gravity to create an air-filled space at the bottom of the bag. The air-filled space forces the sludge to expand, and it is squeezed out of the bottom of the bag, producing a much drier cake in less time than traditional methods.